18018211859

The core content of the company's after-sales support system

The company's after-sales guarantee takes "rapid response, efficient solution, and continuous optimization" as the core, and builds a closed loop of service around the whole cycle of customer use, covering four key links: problem response, technical support, traceability improvement and return visit optimization, and makes every effort to reduce the risk of customer equipment use and improve the experience.

In terms of response efficiency, establish a "48-hour after-sales response mechanism". After the customer feeds back the problem, the after-sales engineer will take the initiative to contact within 1 hour and initially troubleshoot the fault through phone and video; if on-site maintenance is required, it will arrive at the customer's site within 24 hours (within 48 hours in remote areas) to avoid affecting production due to equipment downtime. For related problems in the production process (such as assembly defects), the after-sales department will immediately link up with production technicians and give priority to allocating resources to ensure that routine problems are solved within 72 hours, and complex problems do not exceed 5 working days.

At the technical support level, "full-scenario supporting services" are provided. When the equipment is delivered, it is accompanied by the "Instruction Manual", "Maintenance Manual" and "Parts List" to clarify the daily maintenance steps (such as cleaning the guide rail every month, checking the screw torque every quarter) and common troubleshooting methods; for equipment that needs to be assembled and debugged on site, technicians are dispatched to assist and carry out operator training at the same time, covering equipment start and stop, parameter setting and simple fault handling, to ensure that customers can use it independently and smoothly.

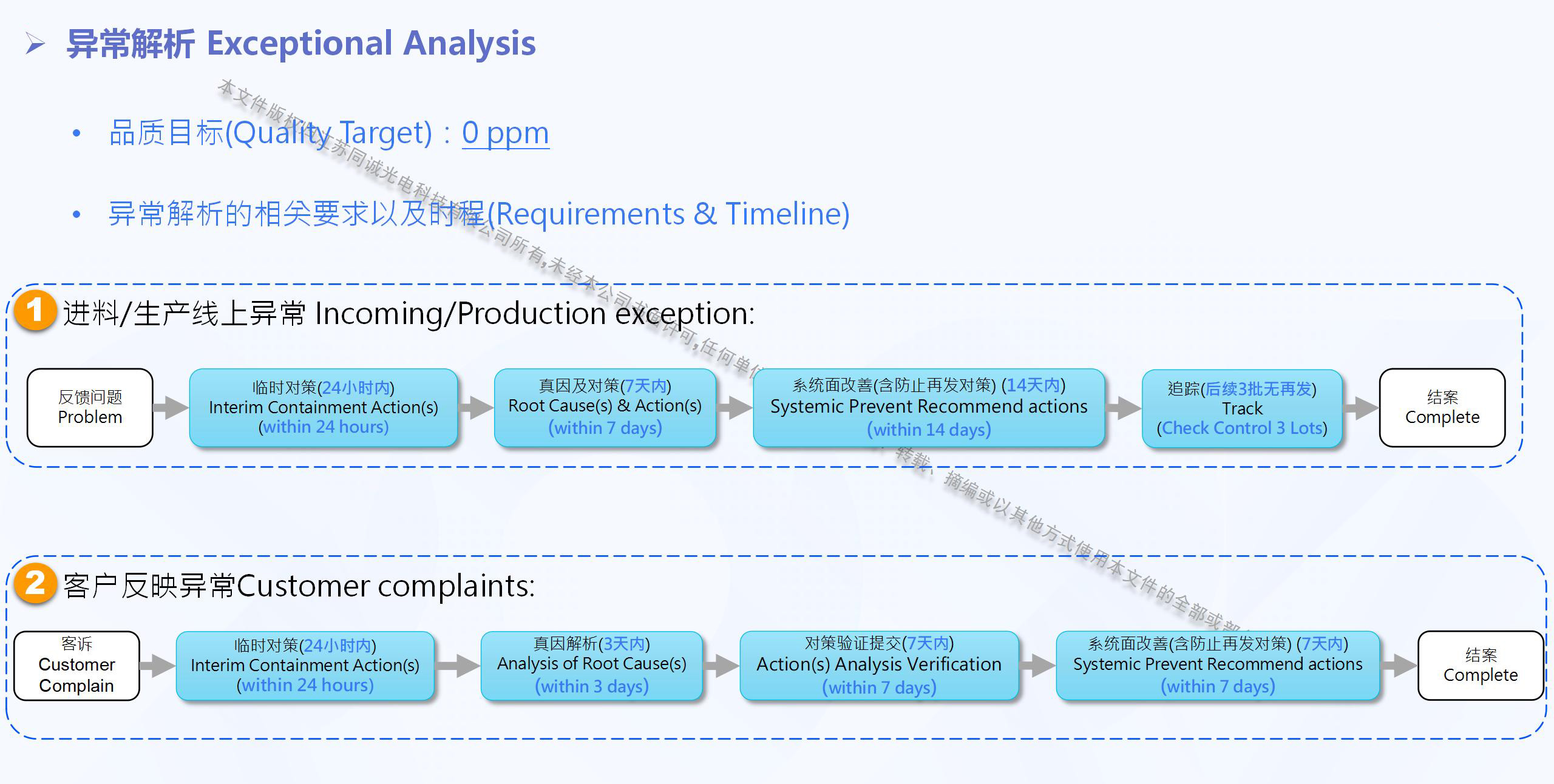

At the same time, after-sales guarantee is linked to the production end to form a "closed loop of traceability improvement". Establish an "after-sales quality problem ledger" to record in detail the fault phenomena, product batches and other information reported by customers, and count the "TOP3 quality problems" every month. The joint production and technical departments analyze the root cause, and if it is a problem in the production process (such as leakage caused by irregular sealant application), immediately optimize the production SOP (such as clarifying the application amount standard), and track the follow-up product feedback to verify the improvement effect, realize the traceability of the whole process of "problem discovery-analysis-rectification-verification", and reduce the recurrence of similar problems from the source.

In addition, the "regular return visit optimization mechanism" is implemented. 3 months and 6 months after product delivery, the after-sales team takes the initiative to visit customers to understand the operating status of the equipment, collect suggestions for use (such as inconvenient disassembly of a part), and timely feedback to the production department to adjust the assembly process (such as adding convenient handles). Through return visits, we can not only investigate potential hidden dangers in advance, but also continuously optimize services according to the actual needs of customers, so that after-sales guarantee can shift from "passive problem solving" to "actively improve experience", effectively protecting the long-term interests of customers.