18018211859

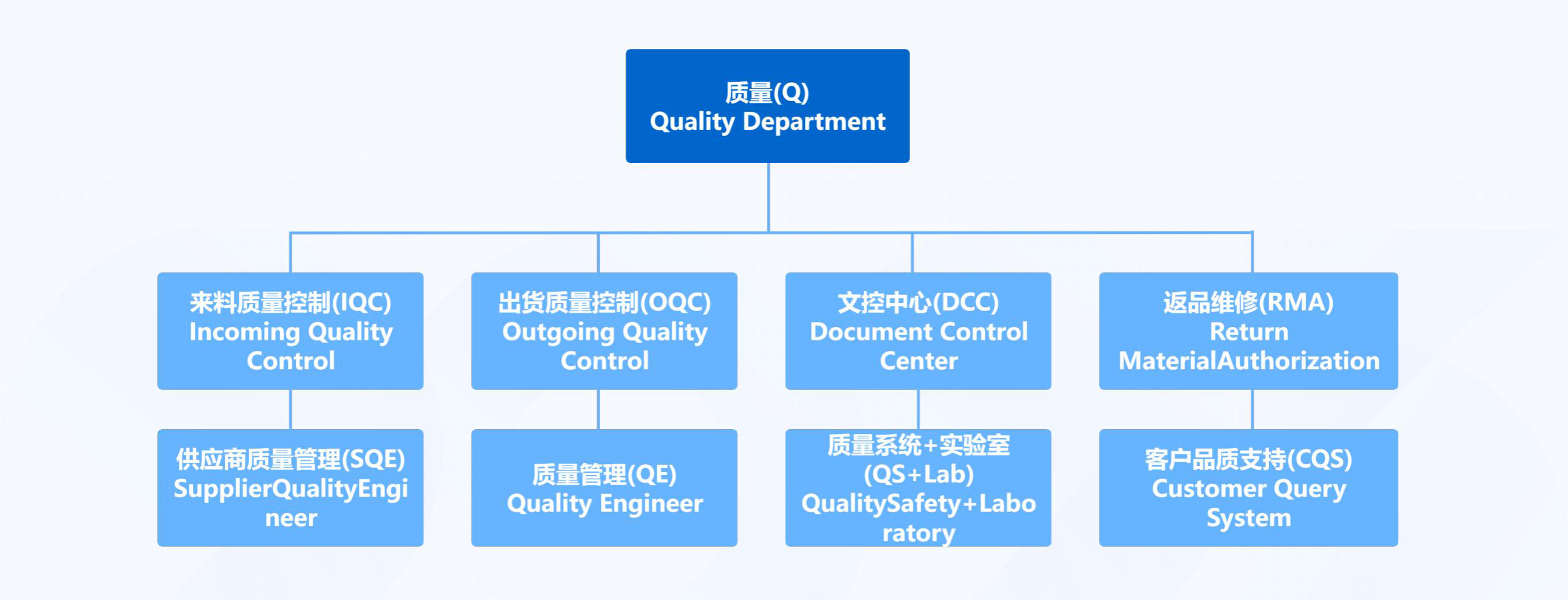

1. Quality control: build a full-chain closed-loop system from source to terminal

The quality control of the company's production link is not a single link of "post-inspection", but a full-cycle management that runs through the "supply chain access→ production process control→ finished product factory verification→ and after-sales quality traceability", and ensures that the quality of each product is stable and up to standard through standardized mechanisms, precision tools and digital means.

(1) Supply chain access: build a "first line of defense" for quality

The foundation of quality starts from upstream parts, and the company avoids quality risks from the source through the "supplier hierarchical management + factory full inspection mechanism":

Supplier Access and Classification: Establish the "Supplier Access Evaluation Standards" to strictly audit new suppliers from four dimensions: qualification (ISO9001/16949 certification), production capacity, past supply quality (defect rate in the past 3 years), and R&D capabilities. Implement "ABC rating" for existing suppliers (Class A: quality pass rate≥ 99.8%, delivery on-time rate ≥99%; Category B: Pass rate 99%-99.8%, punctuality rate 98%-99%; Class C: lower than Class B standards), Class A suppliers will be given priority to obtain orders, and Class C suppliers will rectify within a time limit, and the cooperation will be terminated if the rectification fails to meet the standards.

Parts incoming inspection (IQC): Set up an independent IQC inspection area, equipped with two-dimensional imagers, tensile testing machines, conduction testers and other professional equipment, and formulate differentiated inspection plans for different parts:

Core components (such as motors, circuit boards): 100% full inspection, detecting dimensional accuracy (error ≤± 0.02mm), electrical performance (on-resistance≤5Ω), appearance defects (no scratches, deformation);

Auxiliary components (such as screws, wiring harnesses): adopt the "GB/T 2828.1" sampling standard, the AQL value is set to 1.0, and can only be put into storage after passing the sampling test;

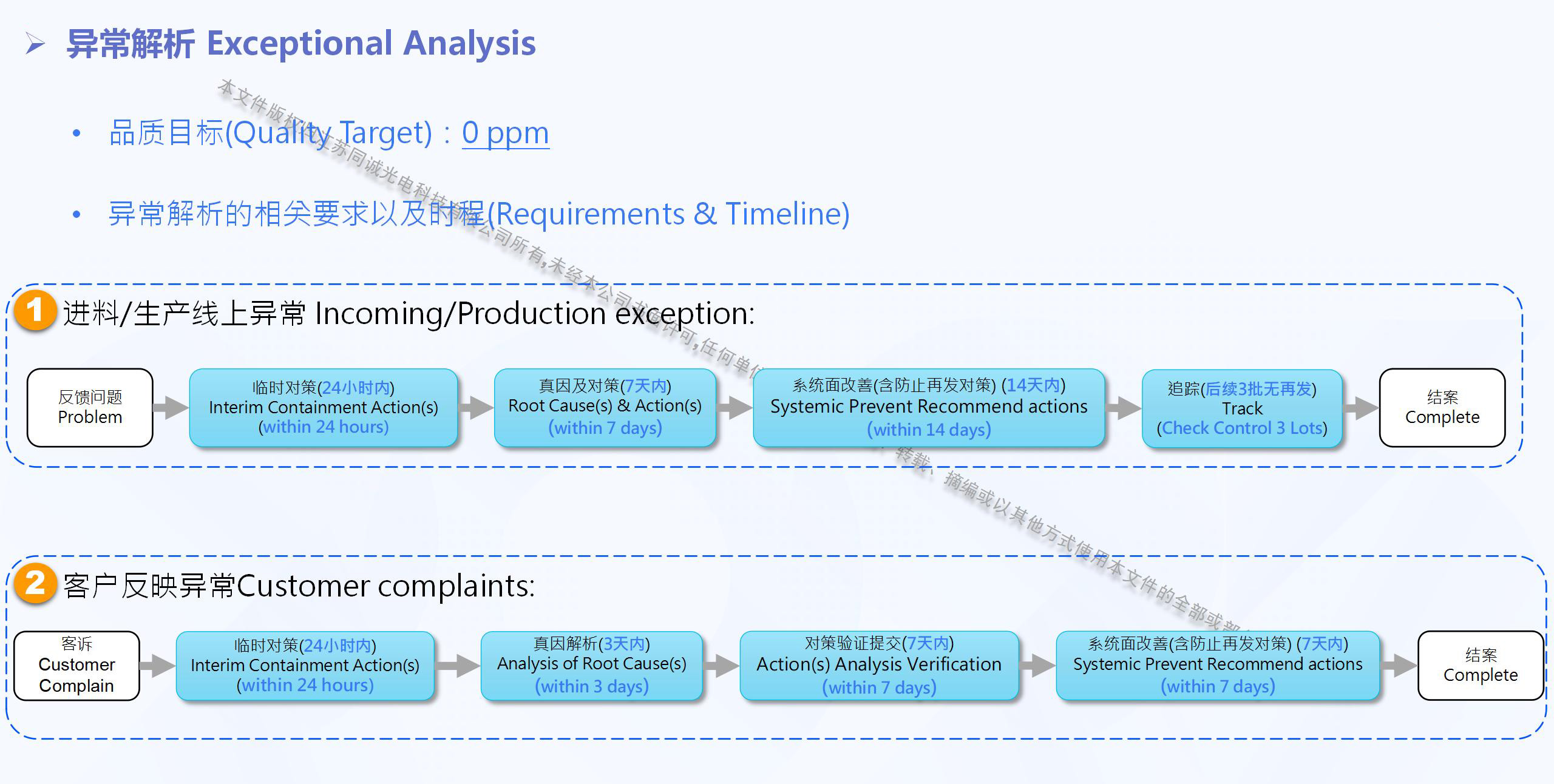

Abnormal handling: If unqualified products are found, immediately start the "Non-conforming Product Control Process", label and isolate, record the ledger, and synchronize the procurement department and suppliers, requiring a rectification plan to be given within 48 hours to avoid defective parts flowing into the production process.

(2) Production process control: to achieve "dynamic error prevention + accurate traceability"

The production process is a key link in quality fluctuations, and the company controls quality risks in the bud through "standardized operation + process inspection + digital monitoring":

Standardized operation system:

Post the "Production Operation Instructions (SOP)" at each station to clarify the operation steps (such as "the motor installation needs to align the locating pins first, then tighten 4 M5 screws, and the torque is controlled at 8-10N·m"), tool specifications (such as "use torque wrench model XX"), and quality judgment criteria (such as "no loose terminals, no crossing of wiring harnesses") to ensure the consistency of operation by different operators;

Implement the application of "error-proof tooling": design exclusive positioning tooling for parts that are easy to install (such as symmetrical shells) to avoid reverse installation; For key processes (such as circuit board soldering), use automated equipment (reflow soldering oven) and set a fixed temperature curve (150°C in the preheating zone and 250°C in the soldering zone) to reduce manual operation errors.

Process inspection and mutual inspection mechanism:

Set up full-time IPQC inspectors to inspect the products on the production line according to the frequency of "every 2 hours / time, 5 pieces per sampling", focus on verifying the "key characteristics" (such as parallelism and sealing performance after equipment assembly), and fill in the "Process Inspection Record Form", and immediately stop the production of the station if abnormalities (such as parallelism deviation >0.1mm) are found, and the technical department analyzes the reasons (such as tooling wear and deviation of operating techniques), formulates rectification measures before resuming production;

Implement the "workstation mutual inspection" system: the operator of the next process needs to check the product quality of the previous process first, such as "missing screws, wiring harness joints are not plugged in tightly" and other problems, can refuse to accept and feedback to the team leader, forming an atmosphere of "everyone manages quality".

Digital Monitoring and Traceability:

Introduce MES (Manufacturing Execution System) to assign a unique "production traceability code" to each product, record information such as "parts batch, operator, production time, inspection results", etc., and if there is a quality problem in the future, the traceability code can be used to quickly locate the responsible link (such as a batch of product is poorly sealed, it is traceable that an operator did not apply sealant according to SOP requirements);

Cameras are installed in key processes (such as precision component assembly) to monitor the operation process in real time, making it easy to review and analyze the root cause of quality problems.

(3) Factory verification of finished products: ensure "zero defect delivery"

Before the finished product leaves the factory, the company passes the "full performance test + final appearance inspection + third-party certification" to prevent unqualified products from entering the market:

Full performance testing: Build exclusive test stations according to product types, such as for automation equipment:

Functional testing: Simulate the actual usage scenarios of customers, test the operating speed of the equipment (such as "whether the conveyor belt speed reaches 1m/s"), accuracy (such as "whether the positioning error is ≤±0.05mm"), and stability (continuous operation for 24 hours without failure);

Reliability test: Through high and low temperature chambers (-40°C~85°C) and vibration testers (10-500Hz), the performance of the equipment in extreme environments is tested to ensure that it meets the customer's working conditions.

Safety test: Testing the insulation resistance (≥100MΩ) and grounding resistance (≤0.1Ω) of the equipment to meet safety standards such as GB 4789.1.

Final appearance inspection: Arrange full-time OQC inspectors to conduct a comprehensive inspection of the appearance of the finished product, including "surface spraying uniformity (no sagging, color difference), nameplate marking clarity (no blurring, misprinting), and component connection gap (≤0.2mm)" to ensure that the appearance meets the customer's order requirements.

Third-party certification: For products involving industry mandatory standards (such as medical equipment and auto parts), entrust third-party organizations such as SGS and TUV to conduct testing and certification, obtain the "Product Conformity Certificate" and then deliver it to customers to strengthen quality credibility.

(4) After-sales quality traceability: form a closed loop of "continuous improvement"

Even after the product is delivered, the company still improves the quality of the production process through "after-sales feedback collection + root cause analysis + process optimization":

Establish an "after-sales quality problem ledger" to record customer feedback on "fault phenomena (such as equipment noise, functional failure), occurrence time, product batch", and monthly statistics of "TOP3 quality problems" (such as "motor abnormal noise accounts for 30%, seal leakage accounts for 25%");

Organize a "quality improvement meeting" to jointly analyze the root cause of the problem with production, technology, and after-sales departments (such as "motor noise is due to the accuracy of a certain batch of bearings is not up to standard, seal leakage is due to the unclear amount of sealant in the SOP"), and formulate improvement measures (such as changing bearing suppliers, updating SOP to increase the application standard);

Implement improvement measures into the production process, track the after-sales feedback of subsequent products, verify the improvement effect (such as reducing the incidence of motor abnormal noise problems from 30% to 1% after the bearing supplier is replaced), forming a closed loop of "feedback-analysis-improvement-verification".

2. Service guarantee: Create a multi-dimensional support system from demand to delivery

The company's "service" in the production process is not "after-sales maintenance" in the traditional sense, but extends to the full-cycle service of "pre-production demand docking, production progress synchronization, and post-production technical support", while covering "external customers" and "internal collaboration" to ensure production efficiency and customer satisfaction through service.

(1) For external customers: full-cycle service with "demand as the core"

Pre-production: In-depth docking of customized needs

In response to the customer's customized product needs, a "production and marketing research special team" (composed of production managers, sales, and R&D engineers) was established to clarify the customer's "technical parameters (such as equipment size, load capacity), delivery cycle, and usage scenarios (such as high-temperature workshops, dust-free environments)" through on-site research and video conferences;

The production department participates in the demand review, evaluates the "production feasibility" (such as "whether the equipment size required by the customer is suitable for the existing assembly line, whether new special tooling is needed"), and feedback to the customer on "production cycle decomposition (such as 7 days for parts procurement, 10 days for assembly, 3 days for testing), cost estimation, and potential risks (such as long delivery cycle for special parts)" to ensure that demand matches production capacity;

Provide "production process preview service" for first-time cooperative customers, invite customers to visit the production workshop, introduce quality control links (such as IQC inspection, process inspection), and enhance customers' confidence in product quality.

In production: transparent progress synchronization and flexible response

Establish a "customer progress synchronization mechanism": send the "Production Progress Report" to customers through email and enterprise WeChat every week, and clarify "the current process (such as 'parts have been put into storage and entered the assembly stage'), completion ratio (such as '50%'), estimated delivery time, and whether there are any abnormalities";

If there is a production abnormality (such as delayed arrival of parts, equipment failure), notify the customer within 12 hours, explain the cause of the abnormality, the scope of impact (such as "the delivery cycle may be delayed by 2 days") and the solution (such as "start a backup supplier, adjust the production shift to catch up with the schedule") to avoid passive waiting;

Respond to customer temporary needs: If the customer puts forward reasonable needs such as "fine-tuning the size of a certain component and adding logos" during the production process, the production department and the R&D department will evaluate and adjust the cost and cycle, and give a reply within 24 hours to meet the customer's personalized demands as much as possible (such as a customer requesting to add the company logo to the equipment shell, the production department can quickly achieve it through laser marking, without additional increase in the delivery cycle).

Postpartum: full-scenario technical support and rapid response

Delivery supporting services: "Product Instruction Manual", "Maintenance Manual" and "Parts List" are provided with the product, which clearly states "equipment assembly principles, daily maintenance steps (such as 'monthly cleaning of guide rails, quarterly inspection of screw torque'), and common fault troubleshooting methods";

On-site installation and training: For equipment that needs to be assembled on site, dispatch production technicians to the door to assist customers in equipment assembly and commissioning, and train customer operators (such as "equipment start and stop operation, parameter setting, simple fault handling") to ensure that customers can use it normally;

After-sales rapid response: Establish a "48-hour after-sales response mechanism", after the customer feeds back the problem, the after-sales engineer will contact the customer within 1 hour to understand the details of the fault; If on-site maintenance is required, it will arrive at the customer's site within 24 hours (within 48 hours in remote areas); If there are problems in the production process (such as assembly defects), the production department will give priority to arranging technicians to assist in after-sales service to ensure that the problem is solved within 72 hours (complex problems do not exceed 5 working days);

Regular return visit service: 3 months and 6 months after the product is delivered, the after-sales department will make a return visit to the customer to understand the use of the equipment, collect "suggestions for optimization of the production link" (such as "a part is inconvenient to disassemble, it is recommended to add a handle during subsequent assembly"), and feedback to the production department for process improvement.

(2) Internal coordination: cross-departmental services with "efficiency" as the goal

The smooth operation of the production link depends on the collaboration of various internal departments, and the company reduces communication costs and improves production efficiency through the "cross-departmental service mechanism":

For the R&D department: feedback on production feasibility and support design optimization

During the assembly process, the production department records "unreasonable design" (such as "the installation space of a component is too small, resulting in low assembly efficiency; a certain interface location is hidden, which is not conducive to subsequent maintenance"), and submit the "Production Design Feedback Form" to the R&D department every week to assist the R&D department in optimizing product design and improving "manufacturability";

Participate in the review of new product development and make suggestions from the production perspective (such as "using standardized parts to reduce customized processing cycles; optimize the connection method of components and improve assembly efficiency") to avoid the disconnection between R&D and design and production capacity.

For the procurement department: Collaborate with supplier management to ensure material supply

The production department provides real-time feedback to the procurement department on "component quality problems" (such as "the strength of a certain batch of screws is not up to standard, the size of a certain component is deviated"), provides inspection reports and unqualified samples, and assists the procurement department in negotiating with suppliers to request rectification or replacement.

Submit the "Material Requirements Plan" to the procurement department 15 days in advance, clarify the "component model, quantity, demand time", and mark the "key components" (such as motors, circuit boards), so that the purchasing department can prioritize supply and avoid production shutdowns and waiting for materials.

For the warehousing department: efficient material docking to reduce circulation loss

Establish a "production-storage material docking process", the production department submits the "material receipt form" every day, and the warehousing department prepares the goods according to the order and sends them to the production line to reduce the time of production personnel to pick materials;

For parts that have not been used yet, the production department assists the warehousing department to do a good job of "protective storage" (such as sealing and storing precision parts, and putting moisture-prone parts into moisture-proof boxes) to avoid material loss.

3. Collaboration between quality and service: build a closed loop of value on the production side

In the company's production system, "quality" and "service" do not exist independently, but form a synergistic relationship of "mutual support and mutual promotion":

Quality is the "foundation" of service: only the quality of the production link (such as qualified parts, accurate assembly, and stable finished product performance) can reduce after-sales problems and make "pre-production demand docking, production progress synchronization, and post-production technical support" more efficient - if the product frequently has quality failures, it will not only increase the after-sales cost, but also reduce the customer's trust in the service;

Service is an "extension" of quality: through "in-depth docking of pre-production demand", the production department can more accurately understand the customer's quality requirements (such as "customers need equipment to operate stably in a high-temperature environment, and the production process can strengthen the selection and testing of high-temperature resistant components"); Through "post-production customer feedback", the production department can find blind spots in quality control (such as "customers report that a certain component is prone to wear, and the production process can optimize the material selection of the component"), and promote quality improvement in reverse;

The ultimate value of the synergy between the two: for example, for a customer's customized automated assembly line, the company's production department ensures that the equipment passes the customer's acceptance (quality assurance) at one time through strict supply chain control and process inspection; At the same time, synchronize the progress every week in the production process, send technicians to the door for training after delivery, and return to collect optimization suggestions (service support) after 3 months - the final customer not only added 2 additional equipment orders, but also recommended 3 customers in the same industry, realizing a virtuous circle of "quality wins trust, service promotes repurchase".

4. Summary: Quality and service are the "twin engines" produced by the company

For the company, the quality control of the production link is the basis of "making products qualified and reassuring customers"; Full-dimensional service guarantee is the key to "making demand land and customer satisfaction". Together, they constitute the "hard power" and "soft power" of the company's production system - through the whole chain of quality control, reduce the production rework rate and improve product reliability; Through multi-dimensional service guarantee, reduce customer communication costs and enhance customer stickiness. At a time when homogeneous competition in the manufacturing industry is intensifying, the dual drive of "quality + service" can not only help the company win the trust of customers, but also build a differentiated competitive advantage, which has become the core support for the company's long-term development.